3S LIFT | A Great Success for CHINA WIND POWER 2024

From October 16 to 18, 2024, the CHINA WIND POWER 2024 (CWP2024) was successfully held. Over a thousand wind power companies from more than 20 countries and regions around the world participated in this annual wind energy event. 3S LIFT showcased our latest products, solutions, and innovative achievements, joining partners in exploring the future of high-altitude safety in wind power. With a focus on technology-driven development, we aimed to explore cutting-edge innovations and achieve enhanced safety upgrades.

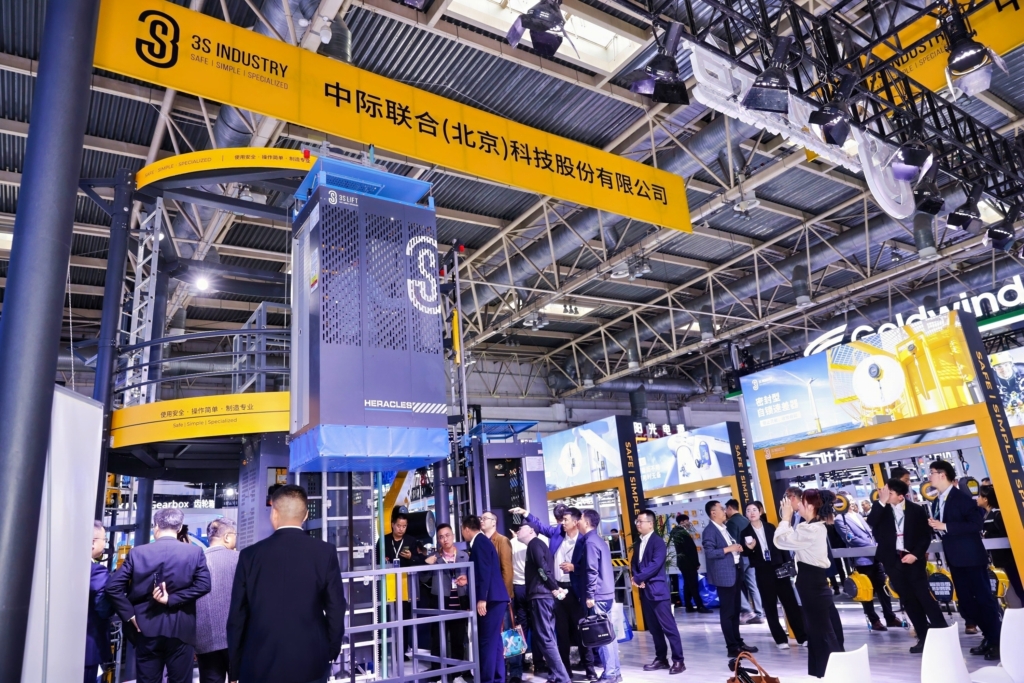

At the 3S LIFT booth, several of the latest technological products and system solutions, designed specifically for the era of high-capacity wind turbines, drew significant attention from industry professionals and experts alike. At this exhibition, 3S LIFT exhibited our comprehensive safety solutions across various sectors and scenarios in wind power, focusing on high-altitude safety lifting equipment, high-altitude safety protection devices, and wireless network coverage solutions. At the booth, industry experts from various sectors explained 3S LIFT innovative achievements and solutions to the visitors, while also exchanging industry insights and experiences.

Exhibition site

During the exhibition, 3S LIFT’s booth attracted significant attention from numerous visitors and partners. The latest technological products and system solutions showcased by the company became the focal point of the event. The rack and pinion service lift that can be used during the construction phase, climb auto system with smart personal fall arrester, wind farm wireless network coverage solutions, and passive smart lock systems earned particular attention.

- Rack and pinion service lift that can be used during the construction phase

This service lift can be directly sent to the tower manufacturing facility for installation and shipped together with the tower. It can be used during the tower erection period, greatly improving efficiency during construction while also significantly enhancing safety. This innovation fills the gap of having no available access equipment during the tower erection phase. The standout features of this rack and pinion service lift are its safety, stability, and efficiency. It utilizes an insulated conductor rail power supply system that replaces the traveling cables with fixed cables, addressing the industry’s common issue of cable retraction difficulties. Additionally, it is equipped with two lifting systems, enhancing its safety assurance capabilities. Thanks to its design of rack and pinion engagement, the service lift effectively avoids vibration during cabin operation, bringing a much smoother performance.

- Climb auto system with smart personal fall arrester

To prevent operators from using the climb auto system without following safety regulations, we developed an intelligent identification system that integrates a safety harness, a smart fall arrester, and a car body. If the system detects that the safety harness or the fall arrester is not connected, the equipment will not start traveling, thereby ensuring personnel safety through technological measures. In addition to the mentioned features, this climb auto system also includes safety upgrades such as monitored hatch cover opening and closing, a car fall arrester with speed detection function, a requirement for simultaneous operation on both hand switches (an interval of over 0.5 seconds will not start the car), and bottom obstruction detection limit switch to avoid obstacles.

- Rack and pinion climb auto system that can be used during the construction phase

Compared to the traditional climb auto system, the rack and pinion climb auto system offers more significant comprehensive advantages. It can be pre-installed inside the tower, allowing for immediate use during the wind turbine construction phase, thereby filling the gap of having no available equipment during the tower installation. With a rack serving as the guide rail and the pinion engagement design, it operates more smoothly than roller track systems. This integrated electromechanical device does not use wire ropes for traction, optimizing the installation process for quick and efficient setup within the wind turbine, which significantly shortens the construction period. Additionally, the absence of wire ropes reduces maintenance and replacement work and associated costs due to wear, resulting in lower overall operational and maintenance expenses.

- 3S Wind farm wireless network coverage solutions

Wireless network coverage can help wind farms achieve safe and efficient operations. In areas without wireless coverage, communication and positioning become challenging, making safety difficult to guarantee. Communication during inspection processes is also hard to ensure, leading to lower efficiency, and connecting devices can be quite cumbersome. The 3S wireless network coverage solution provides comprehensive wireless coverage, offering higher network quality and enhanced data security, while also ensuring that maintenance and management are straightforward and efficient.

- 3S Passive smart lock and control system

The traditional method of “one key for one lock” poses significant security risks, such as the potential for loss or misuse—anyone who finds the key can access the lock, and there is no identity verification or record of unlocking action. In contrast, the 3S passive intelligent lock control system not only ensures equipment security and improves efficiency but also enables data management and traceability for various tasks and processes.

At the international wind power exhibition of this year, we not only displayed cutting-edge products and technologies with a professional and sincere attitude but also strengthened our connections with global customers through exchanges with industry partners from both Chinese and international markets. This engagement allowed us to expand our business scope and market influence. Additionally, we gained a deeper understanding of the future development trends and challenges within the wind energy industry. 3S LIFT will continue to increase its investment in research and development, providing higher-quality products and services, and making a greater contribution to the sustainable development of the global wind energy industry.

As a leading provider of working-at-height equipment and service solutions in China, 3S LIFT is recognized as a national-level demonstration enterprise for sector manufacturing champions, a national intellectual property advantage enterprise, and one of Beijing’s top 100 manufacturing enterprises. To date, 3S LIFT has installed 145,000 personnel lifting devices in 65 countries and regions worldwide, serving over 5,000 wind farms globally.