1. Safe, Durable and easy to Use

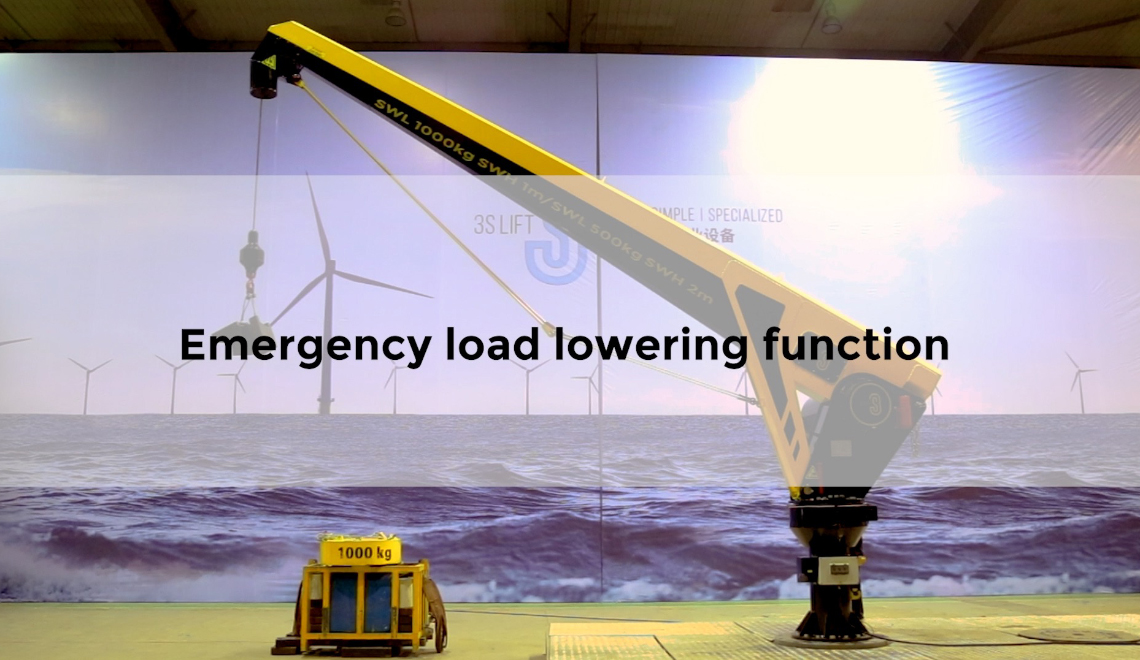

The 24V DC plug-and-play control box is easy to install. Overload protection, mechanical self-locking, and error-proof design ensure safety.

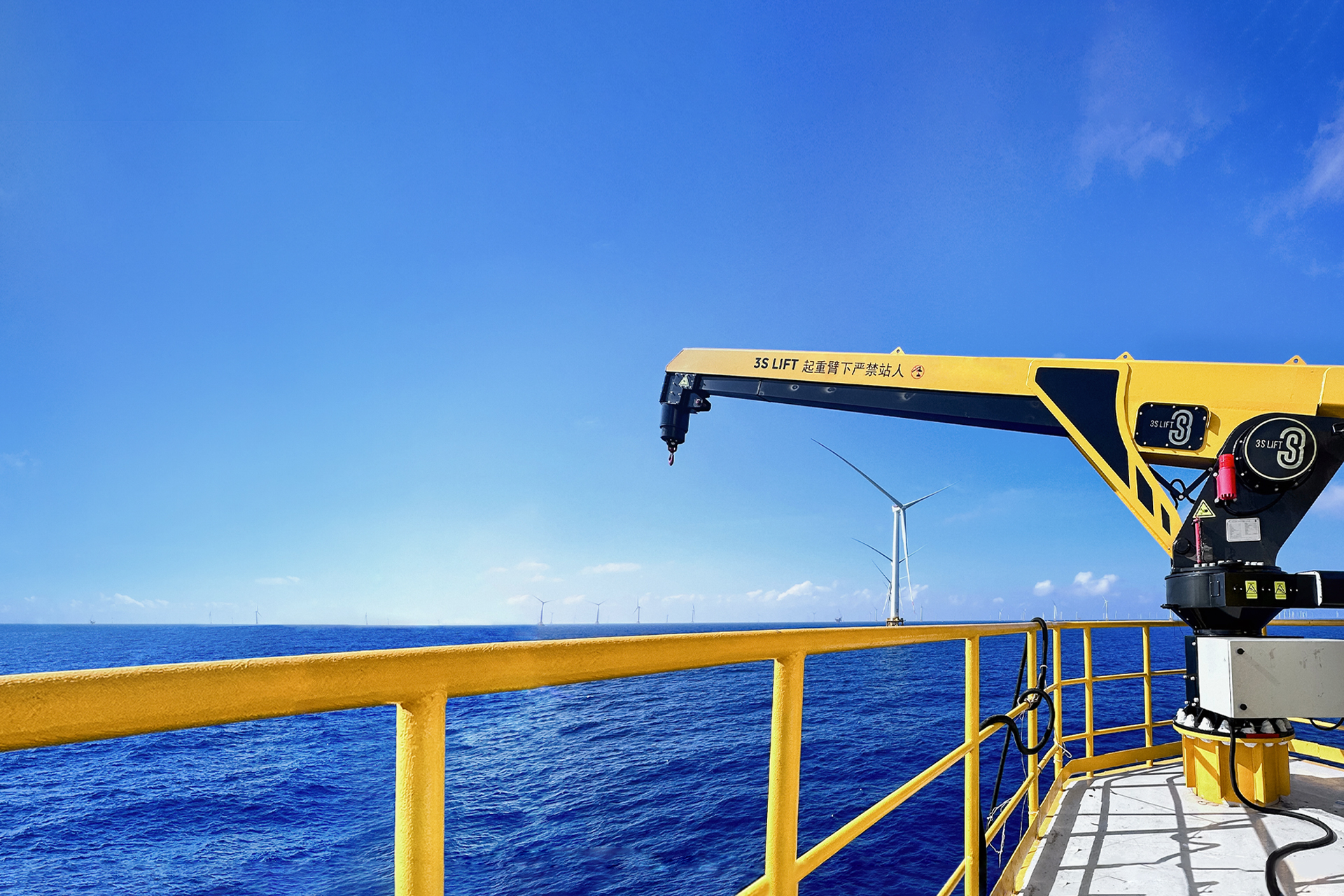

2. Designed for Harsh Ocean Environments

The 3S Lift Offshore Crane is highly safe, reliable, and corrosion-resistant, providing durability and high impact resistance in extreme sea conditions.

3. Cost-Effective and Efficient

The crane minimizes downtime and maintenance, improving efficiency with high-quality components and minimal training requirement.

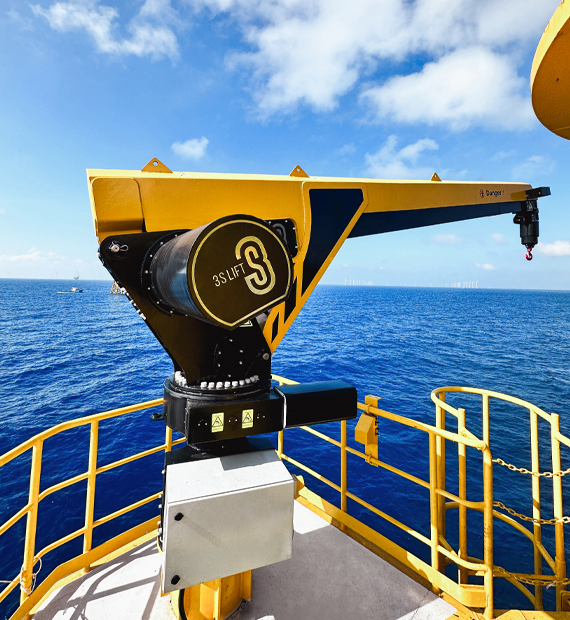

4. Customized Solutions

Adjustable components like mounting platforms, arm lengths, angles, and swivel systems offer tailored solutions for various customer needs.

5. Environmentally Friendly Design

The electric design ensures zero carbon emissions and low noise, supporting sustainable development and meeting eco-certification standards.