Green Transition Takes a New Leap: Rack and Pinion Service Lifts Empower the 150 MW Wind-Solar Hydrogen Project in Duolun

Recently, construction commenced on a 150 MW wind-solar hydrogen production integration demonstration project in Duolun County, Xilingol League, Inner Mongolia. This project employs a co-location strategy for wind and solar power generation, with plans to build 120 MW of wind power capacity. The generated electricity will be stepped up via box transformers and directed to the hydrogen production substation. The project includes the installation of six 6.25 MW turbines and eleven 7.5 MW turbines. A standout feature of the project is the use of 3S Rack and Pinion Service Lifts with a rated load capacity of 480 kg and an operating speed of 36 m/min. Upon completion, the project is expected to deliver 496.902 million kWh of green energy annually, reducing 419,400 tons of CO₂ emissions. This initiative not only enhances renewable energy utilization but also provides clean and efficient energy support for the coal chemical industry, marking a significant step forward in sustainable development.

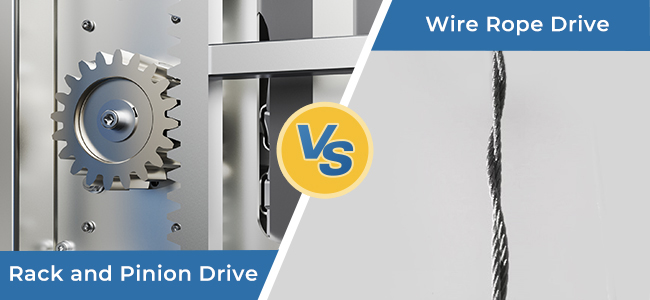

As tower heights continue to increase, higher demands are being placed on the safety and efficiency of access equipment. Rack and pinion service lifts have innovatively adapted to and led this trend, not only enhancing operational safety but also improving efficiency during the construction phase.

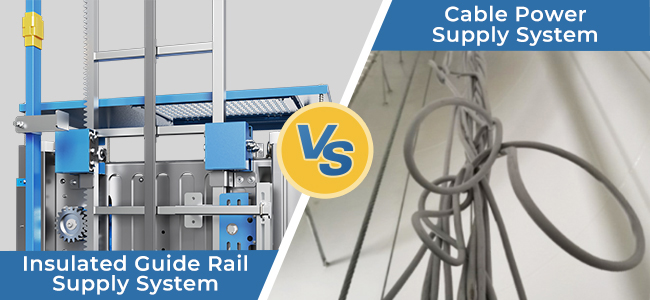

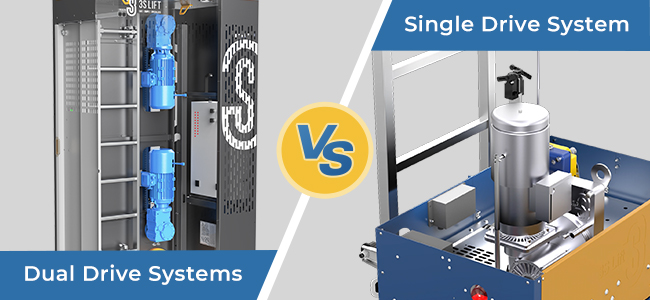

In terms of safety upgrades, the rack and pinion service lift employs an insulated conductor rail power supply system, replacing traveling cables with fixed cables, thereby addressing the industry’s long-standing issue of cable collection difficulties. Unlike traditional lifts equipped with a single power system, it features two built-in hoisting systems, significantly enhancing safety assurance. Additionally, its rack and pinion meshing structure prevents cabin sway during operation, ensuring smoother performance. This design also accommodates various tower types, offering exceptional flexibility and convenience for the construction and maintenance of wind farms.

In terms of load capacity, the rack and pinion service lift has a speed of up to 36 meters per minute, which is twice the speed of traditional lifting equipment. It can accommodate up to four people to reach the top, whereas traditional lifts cannot support larger loads. As the number of wind turbine components and maintenance equipment increases, the demand for higher load capacities and faster speeds has also grown. For example, to transport four people to work at the top of a 120-meter tower and return to the ground, a traditional two-person lift would require six round trips, taking 40 minutes. In contrast, the rack and pinion service lift only requires two round trips, taking just 6.7 minutes—five times faster.

In terms of efficiency improvements, the rack and pinion service lift can be directly delivered to the tower factory for installation and shipped to the project site along with the tower sections. It can be used during the tower erection period, greatly improving efficiency during construction while also significantly enhancing safety. This innovation fills the gap of having no available access equipment during the tower erection phase.

As the wind power industry continues to pursue larger turbines, taller towers, and more diverse tower types, the rack and pinion service lift, with its superior safety and efficiency, has become the ideal choice for climbing large wind turbines. We are committed to driving safety upgrades through technological innovation, continuously improving product quality and service standards. By leveraging advanced technologies, we aim to minimize safety risks to the greatest extent possible, providing safer, simpler, and more professional tower-climbing solutions for the wind power industry. We will also continue to offer products and services that exceed customer expectations, better serving hard-working people in harsh conditions.